- +8618820200782

- info@industrial-chain.com

- Yuanfen Industrial Zone, Shenzhen

- Home

- Chains By Industry

- High Tensile Strength Forklift Chain For Transmission

High Tensile Strength Forklift Chain For Transmission

Elevate Efficiency and Safety with Forklift Chain

In demanding chain applications like forklifts and stackers, where the continuous transport of heavy tonnage materials and frequent lifting operations under substantial loads are the norm, the leaf chain assumes a pivotal role as a safety component. Its durability not only enhances user productivity but also reduces maintenance costs. The reliability of the leaf chain directly impacts property safety and personal well-being!

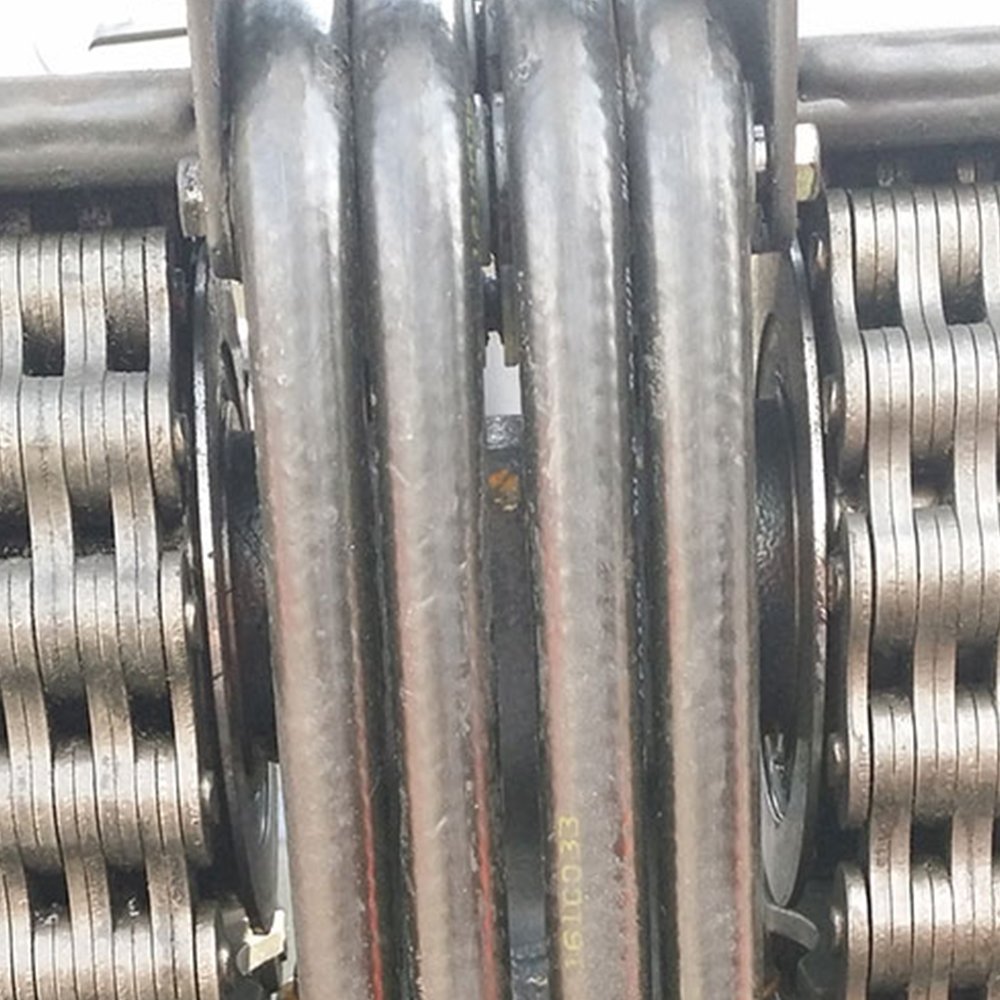

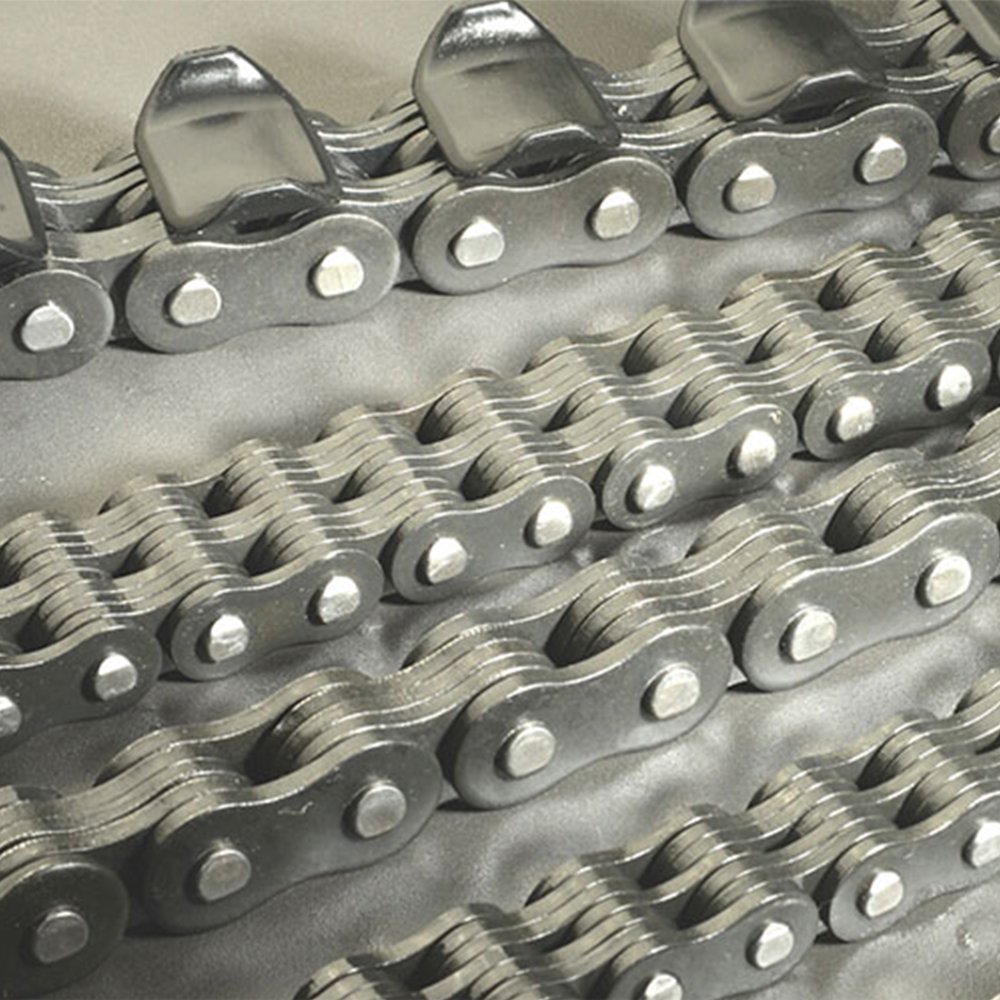

Leaf chains, composed of plates and pins in various lacing configurations, possess superior strength-to-weight ratios and load-bearing capacities compared to their counterparts. Additionally, their robust construction makes maintenance a breeze.

We introduces a fresh perspective and functionality to the conventional leaf chain, elevating your equipment’s lifespan, safety quotient, and cost-effectiveness.

In the research and development as well as manufacturing processes of our leaf chains, our factory adheres to the core principle of “all for safety” and maintains stringent quality control across six key dimensions. Our forklift chains have consistently earned acclaim from customers for their exceptional wear resistance, high strength, and extended service life.

- Premium Materials Only: Our factory exclusively employs high-quality steel from select steel factories, ensuring the stability and reliability of our chains.

- Precision Molds with Intellectual Property Rights: Key quality parameters such as plate holes, pitch, and hole surfaces significantly impact chain robustness, load-bearing capacity, and fatigue resistance. Our factory employs high-precision molds and tooling to attain surface finishes of 80% and above.

- Top-Notch Heat Treatment and Surface Finish: Our factory adopts the latest continuous mesh belt furnace for parts’ heat treatment, guaranteeing top-quality and consistency. Shot peening is applied to all leaf chain components, substantially improving fatigue strength.

- Optical Image Inspection: Prior to assembly, all leaf chain pins undergo 100% optical inspection, eliminating the reliance on human judgment to detect defects and minimizing quality risks. Optical detection is also employed to identify missing components and assembly flaws in finished chains.

- Automated Assembly and Real-Time Inspection: Our company has developed an integrated assembly and inspection line encompassing seven crucial stages: assembly, mechanical and magnetic missing parts detection, pin length verification, riveting, pre-stretching, oiling, and cutting. This streamlines production, enhances efficiency, and reduces reliance on manual labor. All chains are pre-stretched, enhancing fatigue strength and facilitating straightforward assembly.

- Comprehensive Quality Tracing: Wonkechain adopts a lean production model, collecting and inputting all production and inspection data into the Group EAS system. This ensures meticulous quality tracing, extending from raw material suppliers to specific material batches.

- Flexible Delivery Options: Chains can be supplied in rolls or with screws, according to customer preferences.

- Rapid Responsiveness: Our factory maintains a dedicated leaf chain manufacturing department and a proficient marketing team. With a substantial inventory, we respond promptly to customer requirements.

- Complete Range of Forklift Chains & Accessories: Our factory offers a comprehensive selection of forklift chains and accessories, including AL series, BL series, and LL series leaf chains, silent chains for hydraulic oil pumps, chains with groove attachments, and chains with screws. Depending on the forklift’s operating environment, we provide three surface treatment options: phosphating blacking, Dacromet, and natural color.

- Customized Chain Development: Our factory has a strong track record of supplying chains and accessories to OEMs, offering customization and development services, as well as comprehensive lubrication and rust prevention solutions.